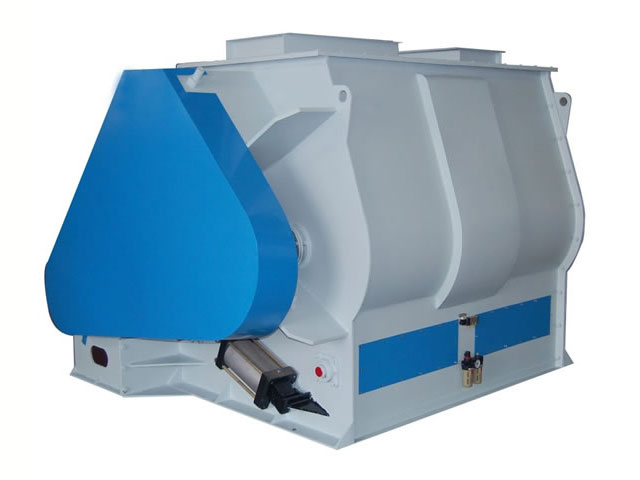

Performance features:

Low operating speed, even heights(CV≤5%), segregation-free; fast discharging, small amount of residue, excellent sealing property of doors; stable transmission, small friction; convenient maintenance; beautiful in appearance, no environmental pollution; mixed evenly in the weightless condition, the material is free from the influence of granularity and volume-weight. Numerous paddles with special angles are soldered on the rotor; at the both sides of the rotor sit scrapers; the gap between blades and chassis is very small. Bottom-dump dual doors discharge material with its doors wide open. The door is opened to 90 degree, which ensures the least amount of residual material;

Pneumatic controlling devices; the discharging door shares the same curvature as the bottom tank of the mixer base; reasonable sealing device and four finishing discharging doors ensure no material leakage. Dual rows chain transmission with high strength; achieve the optimal rotate speed of main shaft, large transmission torque; increase productivity; transmit with less noise and in a more stable manner. Many a atomization nozzle. Choose famous bearings. Adopting spherical roller bearing as the mainshaft bearing, the mixer has a long service life. The door on the closed trough is set for overhauling and cleaning, and it is convenient to operate and clean it.

Range of application: it is widely used in the mixing of material in the shape of powder, pellets, plate, bulk, and gelatinization in the field of feed, food, chemical industries.

Major Technicai Parameters

| Product model | SJH0.5 | SJH1 | SJH2 | SJH4 | SJH7 | SJH8 |

|---|---|---|---|---|---|---|

| Main engine power (KW) | 5.5 | 11 | 18.5 | 30 | 37 | 45 |

| production capacity (kg/p) | 250 | 500 | 1000 | 2000 | 3000 | 4000 |